TURNAX company. Machine design and manufacturing:

We build prototype and special-purpose machines from design to manufacture.

We are a manufacturer of :

- CNC multi-axis automatic lathes for metalworking different types : longitudinal, multi-spindle, rear-end machining with synchronized spindle or simple kinematics, special purpose customized for complicated and non-standard details

- modular numerical turning-milling machines

- customized lathes and milling machines

- carousel machining centers drilling – chamfering – threading

- special purpose CNC grinders

Automated machining, services:

- design and manufacture of CNC-controlled precision machining machines

- manufacture of special purpose machines

- production lines design and manufacture

- design and manufacture of spindles, electro-spindles for CNC machines

- construction of special functional components of the machine (mechanical clamps, chucks)

- retrofitting of machines in the field of comprehensive replacement of CNC computer with a modern one controller (Sinumerik, Fanuc, NCT)

- building a machine in combination with robotics and industrial automation

- CNC, PLC, HMI design and programming

Our realizations:

We designed and built the following machines on special order for special dedicated parts.

Turnax Speedax TRN A42 CNC automatic lathe machine

Turnax Speedax B42 CNC automatic lathe machine

Drilling – chamfering – threading carousel machining center TRN C35

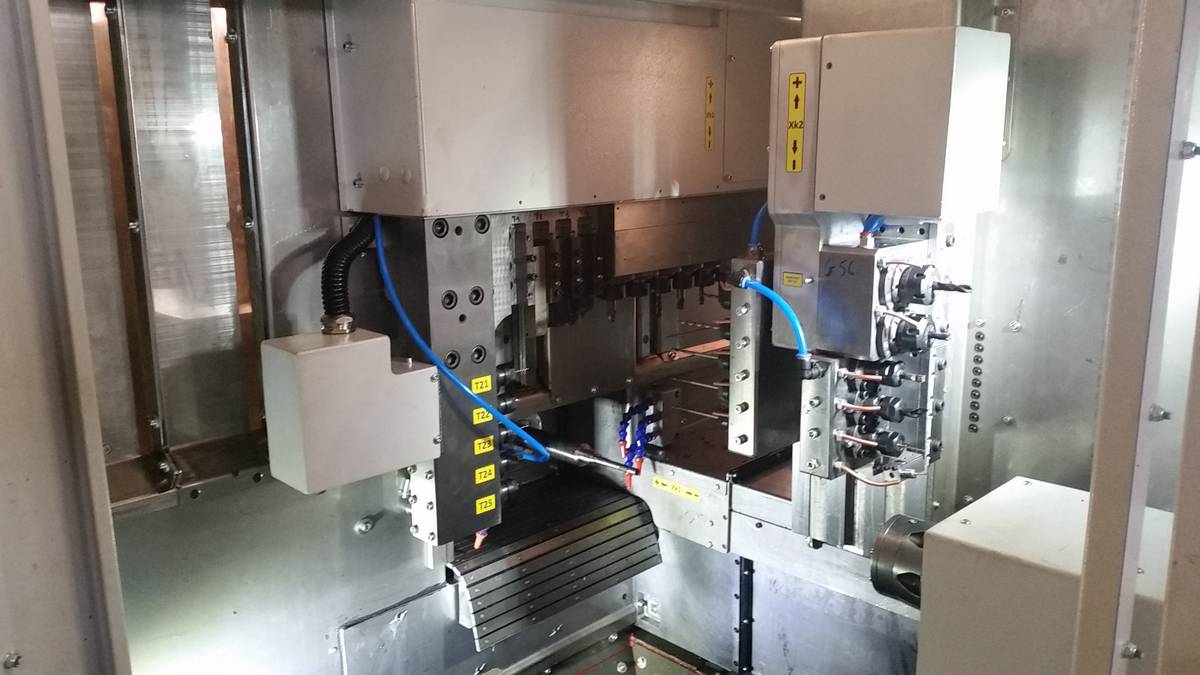

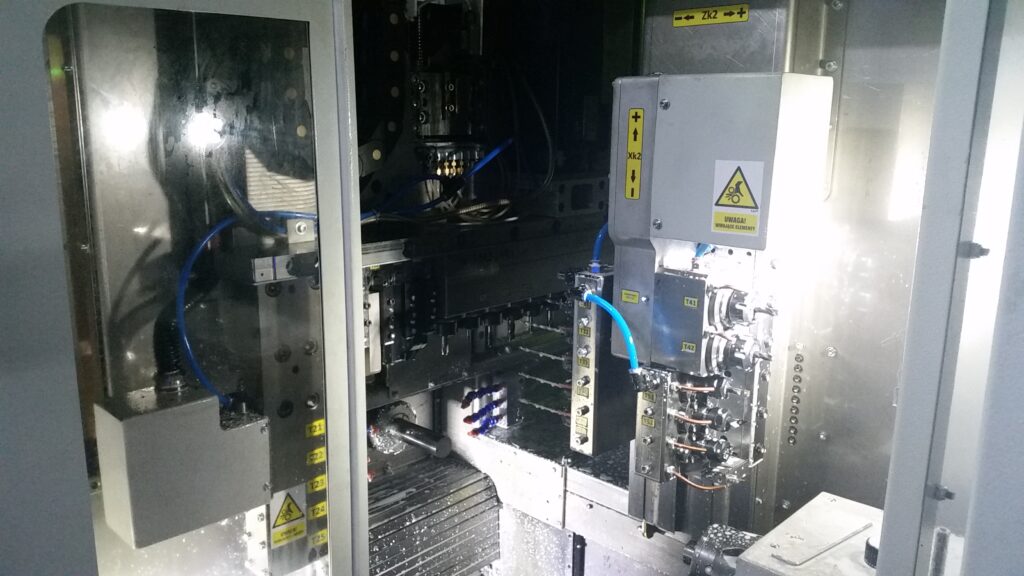

Turnax Speedax TRN A42 CNC automatic lathe machine

- two separate CNC channels

- number of spindles: 2 (S1,S2)

- number of numerically controlled axes: 6+2

- power of spindles 7 kW / 3 kW

- through-hole of spindles: 42 mm

- spindle and sub-spindle clamping: pneumatic / pneumatic

- X1 axis range: 320 mm

- Y1 axis range: 240 mm

- Z1 axis range: 200 mm

- X2 axis range: 220 mm

- Z2 axis range: 300 mm

- W2 axis range: 600 mm

- C1 axis range:: 360 degrees

- C2 axis range:: 360 degrees

- number of live tools: 8+5+2 (3 groups S3, S4, S5)

- bar feeder with magazine

Turnax Speedax B42 CNC automatic lathe machine

Spindle:

- main spindle power: 5kW (option up to 47 kW)

- maximum rpm: 4500 rpm (option up to 16000)

- through-hole: 42 mm

- main spindle collet: 173E

- spindle bearings: NSK B7013

- collet clamp: mechanical

X,Z axis:

- travel distance 300mm

- power of servo drives: 1kW

- maximum travel speed: 30000 mm/min

- power transmission: ballscrews Fi25

- ballscrews support: ZKLF2068

- linear guides: HIWIN HGH25

Tool clamping:

- tool bar (turret head option)

Bar feeding:

- barfeeder 3000 mm

- bar ejection: hydraulic

- bar stabilization: hydraulic

Options:

- Y axis

- subspindle

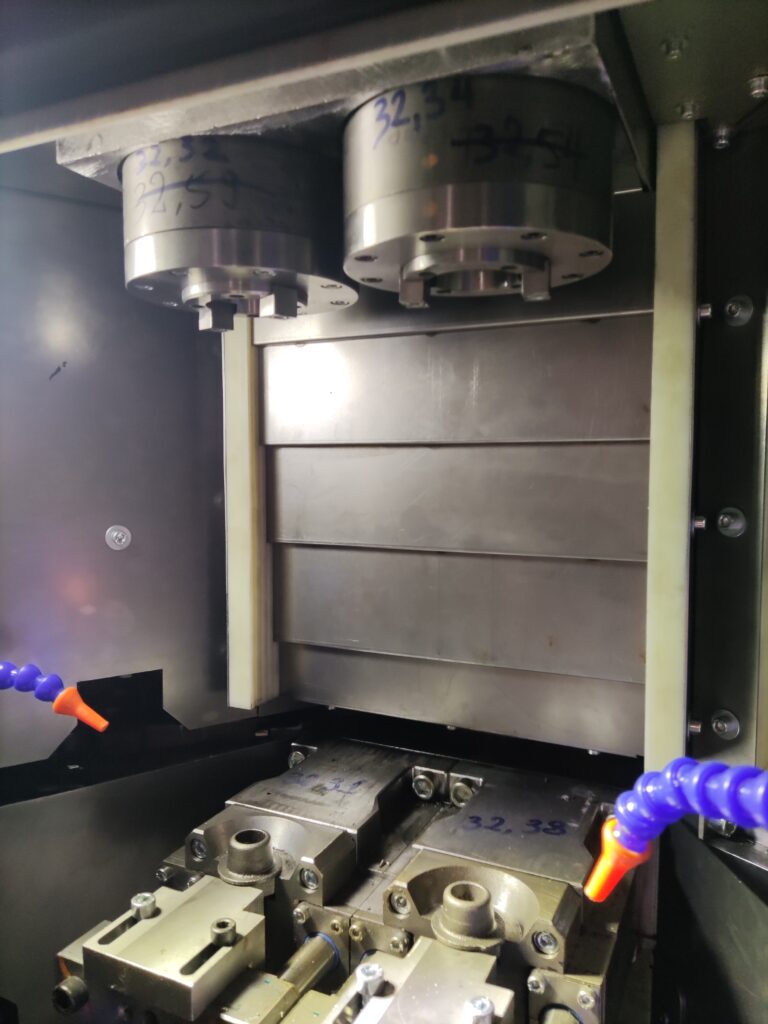

Drilling – chamfering – threading carousel machining center TRN C35

3 working stations:

1st station axis Z1:

- two drilling spindles driven by 7.5kW motor, cooling through the spindle, stroke 250mm, ISO40 mounting

2nd station axis Z2:

- two drilling (turning) spindles driven by 10kW motor, external cooling, stroke 250mm, ISO40 mounting

3rd station axis Z3:

- two tapping spindles, synchronized with servo feed, stroke 250 mm, servo power 5.5 kW, ISO40 mounting

Operator Station:

- unloading and loading station, uninterrupted change of workpieces during processing

TURNAX

Nowe Gizewo 28A

12-100 Szczytno

POLAND

mob. +48 691404566

e-mail: info@turnax.com

website: www.turnax.com

Company branches:

Warszawa, Ciechanow, Legionowo, Zielona Gora